Fresh concrete composite system

What is a fresh concrete composite system?

The term “fresh concrete composite system” generally describes the technology for waterproofing buildings using a fresh concrete composite membrane. Here, the fresh concrete composite membrane encloses all parts of the building in contact with soil like an additional protective skin and in this way prevents the ingress of water and radon. The membrane is laid under the floor slab and on the outside walls of the building below ground level. The concrete is then poured and the fresh concrete composite membrane forms a permanent, waterproof bond with the concrete.

What is the purpose of this fresh concrete composite system?

The fresh concrete composite system technology serves as an additional waterproofing measure for buildings. In some cases, concrete constructions in themselves no longer meet the required quality standards. During planning and when carrying out waterproof construction, this results in deficiencies that can subsequently cause sealing issues.

The fresh concrete composite system acts as an additional protective skin for the building and compensates for precisely these deficiencies. The secondary sealing enables classification in a higher basement performance class and thus doubles the reliability of the building seal.

Where can this system be used?

Fresh concrete composite membranes are normally used in conjunction with a waterproof concrete construction. In practice, this is also referred to as “white tank +“ because the fresh concrete composite system is an additional measure applied to the already existing waterproof construction. In isolated cases, combination with in-situ concrete rather than waterproof-quality concrete (normal concrete) is chosen.

What systems are used? what are the differences?

In practice, two systems are preferentially used. One option is the fresh concrete composite membrane with a fleece backing. This backing forms a mechanical bond with the concrete after pouring and hardening. The bond between the fresh concrete composite membrane and the concrete is virtually impossible to detach.

The second system used is an adhesive bond system. Here, the concrete-facing side of the fresh concrete composite membrane is coated with an adhesive layer that reacts with the concrete to create a bond.

In practice, almost all types of fresh concrete composite membranes are based on the two main systems of mechanical or adhesive bonding with the concrete. In terms of the membrane types and their layer structure, however, they differ in the number of layers, material thickness and functionality.

Regulations and standards?

As a recognised state-of-the-art, fresh concrete composite systems have already been in use for a number of years and are widely available on the market today. Nonetheless, no standardised regulations are yet available that define the use and handling of these fresh concrete composite systems. Although waterproofing with bitumen membranes is described in DIN 18533, no mention is made here of fresh concrete composite systems. Likewise, the German DAfStB waterproof concrete guideline does not cover the topic of fresh concrete composite membranes or their application in any detail as the use of additional surface sealing in combination with a waterproof construction is not envisaged.

Planning for buildings with a fresh concrete composite system is therefore largely based on DIN 18533, but also to a certain extent on the German DAfStB waterproof concrete guideline. Because, however, no unequivocal regulations or standards are available, the entire construction method and application can only be seen as being based on existing standards and regulations. Notwithstanding, the fresh concrete composite membranes can be used in consultation with the client and within the manufacturer’s sphere of responsibility. No additional evidence is required for this purpose.

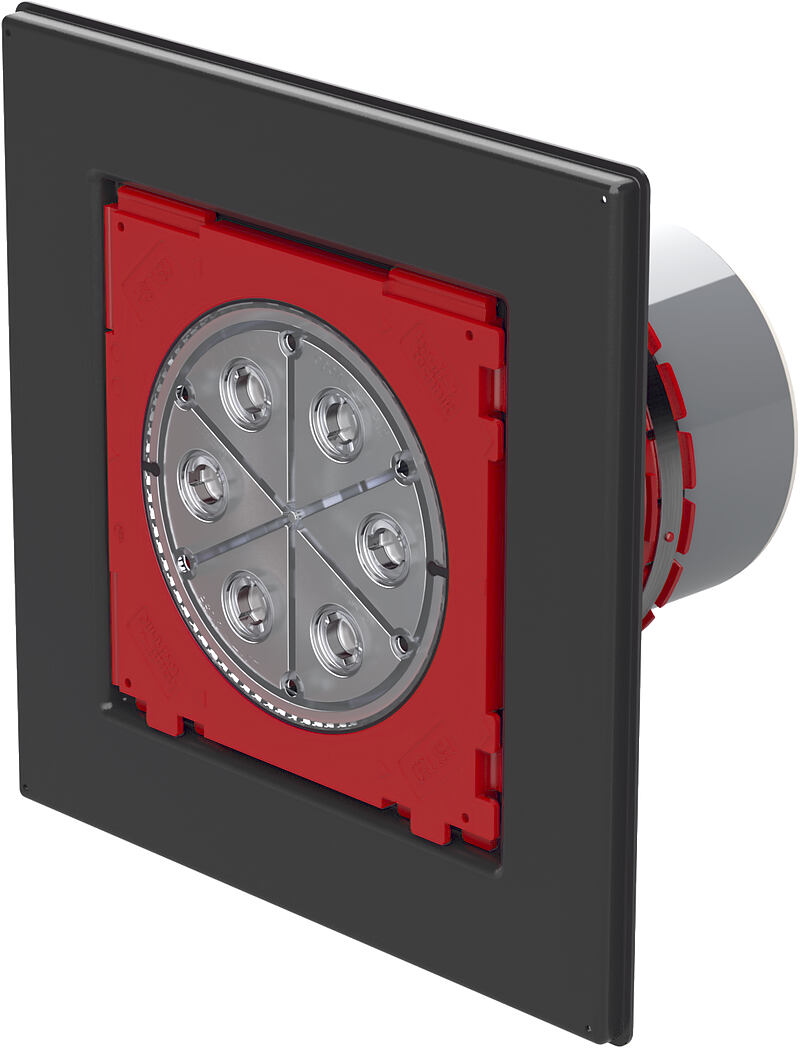

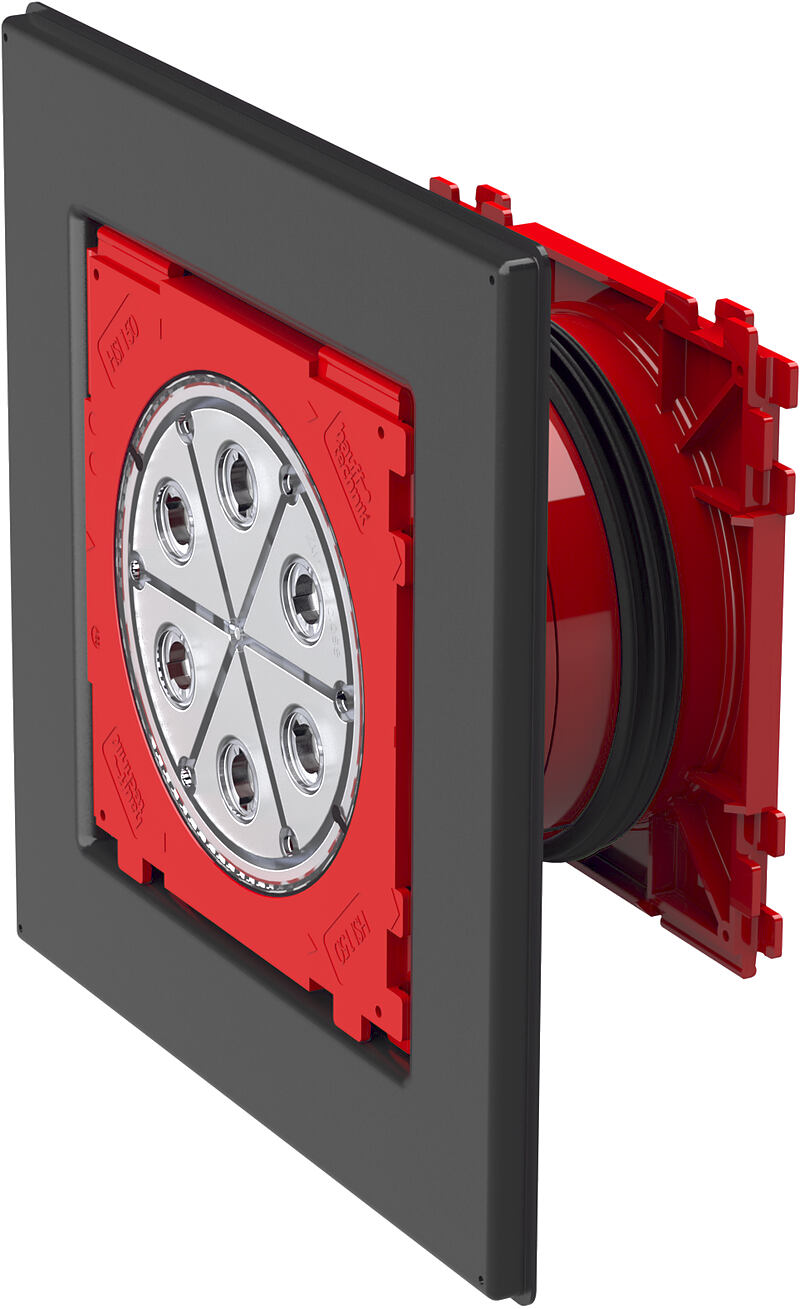

Connection solutions at penetrations

For penetration components and sealing solutions, the system employed must always be coordinated with the manufacturer. The concepts for connection solutions should therefore always be agreed in advance between the manufacturers of the fresh concrete composite system and the manufacturers of the penetrations and sealing system. In the case of solutions testing in combination, reliable connection of the penetration and sealing components to the surface sealing can be assured. Our products are tested together with a variety of fresh concrete composite systems and offer an optimal system solution.